Safety Headwear Buyers Guide

SAFETY HEADWEAR BUYERS GUIDE

Your Guide to Selecting Safety Headwear and Helmets for Your Workplace

Compulsory on British building sites since 1990, the Safety Helmet or Hard Hat is an essential item of PPE if you or your employees work in an environment where there is a risk of being struck by falling or moving objects. This one item can spare workers the threat of head and spinal injuries or even death and unless there is no foreseeable danger, employers must provide hard hats to all employees and visitors onsite.

On almost all construction sites the risks of head injury are great enough that the law requires head protection to be worn by everyone onsite. Construction work should be carefully planned and organised to minimise the risks. For example; preventing objects falling by using scaffolds with toe-boards and, if necessary, brickguards.

If, after organising and planning the work, the risk of head injury still remain, you should ensure that all employees and visitors to the site are provided with, and wear, suitable head protection. This is necessary to comply with the PPE Regulations 1992.

Hard Hats should be:

• In good condition. Inspect them regularly and discard if damaged or deteriorating

• Stored in a safe place onsite, away from direct sunlight and out of excessively hot or humid conditions

• Fit the wearer and be worn properly

• Fit comfortably with other head worn PPE such as Ear Defenders and Goggles

• Only obtained from a reputable supplier and meet safety standard EN397; sadly there are fake helmets on the market

Ensure that Hard Hats are worn onsite by:

• Making it a site rule

• Management and supervisors should set a good example by wearing their helmet when onsite

Cheaper helmets are constructed with a plastic harness inside which can become uncomfortable if worn for long periods of time. These are recommended only for short term use, such as for site vistors. For all day use helmets with textile cradle straps (utilising terylene - a tough but soft fabric) provide greater comfort and are preferred by employees who need to wear their helmet all day.

Section 11(1) of the Employment Act 1989 exempts turban wearing Sikhs from any legal requirement to wear a safety helmet whilst on a construction site. This exemption does not apply in workplaces other than construction sites and there is no such exemption for Sikhs who choose not to wear a turban or for other religious groups.

Our Safety Headwear also includes Bump Caps. These should be used when there is a need to protect the head against accidental bumping, for example on overhead piping or other fixtures. Intended for use in areas that have low head clearance or low hanging machineries, they are ideal for automotive repair, meter reading, maintenance and HGV drivers.

The table below sets out the various safety standards you may see marked on products, and the uses those standards apply to. We also note other markings, and their meanings, that you might come across. We may not stock Helmets for every standard, but if you cannot find the product you need, call us on 08454 65 66 65 and we will do our best to source it for you. All of our helmets meet the legal requirement for Safety Helmets for Industrial Use.

Head Protection Safety Standards and Markings

| EN397 - Industrial Safety Helmets | -20°C or 30°C = Tested at very low temperature |

| +150°C = Tested at very high temperature | |

| 440 V (a.c) = Tested for electrical insulation | |

| L.D = Tested for lateral deformation | |

| MM = Resists molten metal splash | |

| Note that the helmet must also have an attachment for a chin strap. | |

| EN443 - Helmets for Firefighting in Buildings and Other Structures | A = Protects the dome of the skull; or |

| B = Additionally protects the sides of the head; or | |

| A3b = Protects dome of the skull and frontal chin region; or | |

| B3b = Additionally protects the sides of the head | |

| *, **, *** or **** = Tested to -10, -20, -30 or -40°C respectively | |

| E2 = Provides electrical insulation when wet | |

| E3 = Provides surface electrical insulation | |

| C = Resistant to liquid chemicals | |

| EN812 - Industrial Bump Caps | -20 or -30 = Tested at very low temperature |

| F = Resistant to flame | |

| 440 V (a.c) = Tested for electrical insulation | |

| EN14052 - High Performance Industrial Helmets | KS = chin strap provided |

| -20°C, -30°C or -40°C = Tested at very low temperature | |

| 150°C = Tested at high temperature | |

| 7 or 14 = Resistant to radiant heat | |

| 440 V (a.c) = Tested for electrical insulation | |

| MM = Molten metal splash resistant | |

| BS6658 - Protective Helmets for Vehicle Users | |

| EN50365 - Electrially Insulating Helmets for Use on Low Voltage Installations |

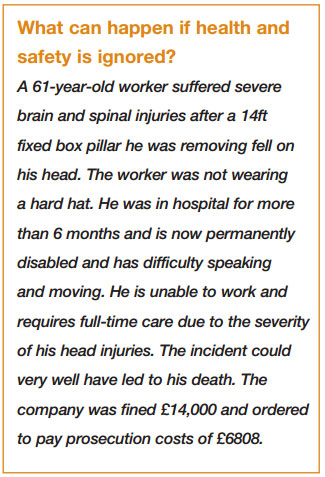

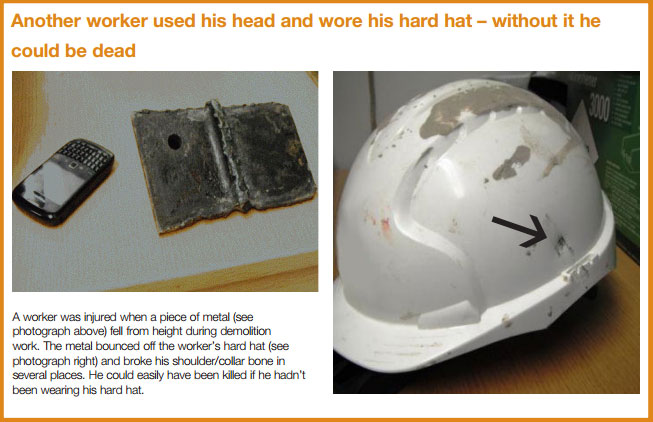

Case Studies

These case studies show the difference that wearing a Safety Helmet can make in the event of an accident. Both of these articles were taken from HSE's publication 'What You Need To Know as a Busy Builder'.